The most important questions on the subject of drawer slide systems.

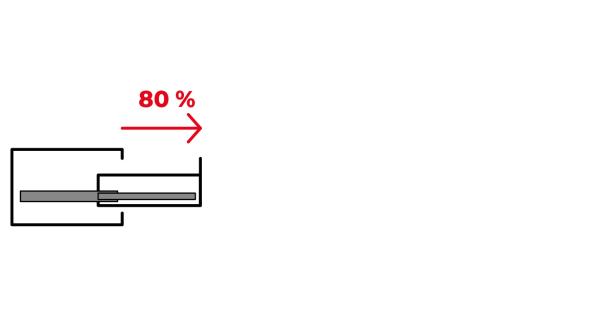

Regular extension drawer slide systems, the drawers cannot be completely extended; part of it remains in the cabinet. Regular extension drawer slide systems are a low-cost, economical solution.

In addition, we offer these regular extension drawer slide systems as a customized option. The highest level of productivity ensures a constant and sustainable market position.

Product features:

- dynamic load capacity from 30 to 100 kg / 66 to 220 lbs.

- nominal lengths from 300 to 1,500 mm / 11.81 to 59.06 in.

- powder coated or galvanised surface

Especially for your requirements we produce regular extension drawer slide systems with different mounting options and fastening techniques.

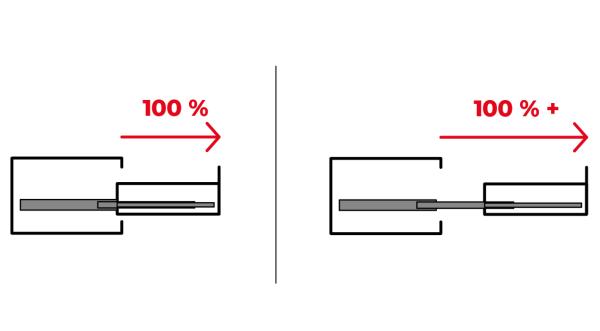

Full extension drawer slide systems, the drawer can be fully extended, with over extension even beyond the front edge of the cabinet.

Progressive action drawer slide systems provide the smoothest running performance. The load in the drawer is equally supported during the full stroke from close to open and vice versa. Telescopic action full extension drawer slide systems function incrementally through stages.

Product features:

- high dynamic load capacity from 30 to 200 kg / 66 to 450 lbs.

- nominal lengths from 200 to 1,200 mm / 7.87 to 47.24 in.

- powder coated or galvanised surface

Regular and full extension drawer slide systems are available in customized design.

Under the ‘Closing method’ heading, it is indicated whether the products are equipped with a gravity self-closing or spring-loaded self-closing system. Both variants ensure that the drawer closes itself during the final part of the retraction movement, without springing back open.

Gravity self-closing:

In the case of roller bearing slides, this function is achieved thanks to the special shape of the cabinet and drawer profiles. The drawer completes the last portion of the closing action itself.

Spring-loaded self-closing:

In the case of ball bearing slides, a spring-loaded system is used to allow the drawer to complete the last portion of the closing action itself.

This feature prevents the drawer from slamming shut by absorbing the initial closing force via a damping cylinder and utilizing aspring mechanism to complete the closing cycle with a very smooth and quiet closing action.

Cabinet profile:

Most of the drawer slide systems are affixed to the side wall of the cabinet, normally using a 32 mm / 1.26 in. pitch.

Drawer profile:

There are different methods of affixing the slides to the drawer / tray:

In the case of bottom mounting, the drawer or tray is resting on top of the runner for the drawer slide. Both roller and ball bearing slides are available in this style.

Side mounting encompasses all mounting positions where the runner for the drawer slides is affixed to the sides of the drawer or tray. Both roller and ball bearing slides are available in this style.

Standard solutions are available for mounting the drawer slides, and special solutions are available on request.

Holes:

Round, elongated or key-hole. Always in the centre of the runner so that the heads of the screws or rivets do not interfere with the rollers.

Bayonet tabs:

Rapid assembly method for fitting our drawer slides to metal cabinets. There are different types and sizes. They can be attached both to the cabinet and to the drawers in whatever manner the customer wishes.

Hanging hooks:

Rapid assembly method for fitting drawer slides in cabinets. The angle bracket on the runner hooks into a pilaster rail on the side of the cabinet.

Mounting brackets:

Brackets affixed to the cabinet profile are used for system drawers with an apron. Various mounting options for affixing to wood or metal. Different models are available for different cabinet sizes.

Angle brackets:

Angle bracket for underframe mounting of drawers with a smaller load capacity or for affixing drawer slides underneath worktops, e.g. in the case of hanging drawers or shelves.

The load capacity value denotes the maximum permissible load that can be borne by the pair of slides for up to 50,000 duty cycles.

All dynamic load values apply only where the drawer slides have been affixed at all mounting holes using appropriate fasteners.

In the case of roller bearing drawer slides, the load capacity values given are for a slide length of 600 mm / 23.62 in. The load capacity of longer slides is around 20% lower.

In the case of ball bearing drawer slides, the load capacity values given are for a slide length of 450 mm / 17.72 in. and a slide width of 450 mm / 17.72 in. The load capacity of longer slides is around 20% lower.

Important note: for optimum results, the drawer should not be wider than the nominal length of the runner for its drawer slide. If the drawer is excessively wide, it will end up tilting at each end of the closing stroke (but not in the middle).

It is the system as a whole, and therefore also the stability of the cabinet and the drawer, that ultimately determine whether the drawer slide can reach its maximum load capacity and service life. We recommend using the entire system in its intended arrangement.

Various types of roller bearings comprised of solid synthetic rollers, synthetic encased steel ball bearings, silent-running roller bearings and chrome steel ball bearings form the running element of these drawer slides.

The runner unit design is based of steel balls caged in a retainer.

In the case of flat-mounted ball bearing drawer slides, the deflection value varies depending on the application. The stresses exerted on the drawer always result in a certain amount of deflection, depending on the load. In the case of certain roller bearing drawer slides, the slides are designed so that they rise up when opened in order to counteract this deflection. We recommend that our customers test the drawer slides in their intended use scenario.

Corresponds to the maximum length of a fully closed slide. Always opt for the maximum possible slide length.

The built-in width is the available space between the runner on the drawer itself and the cabinet or housing.

The material property ESD is relevant to office workstations, as it helps to protect electronic devices against unwanted discharges.